The ACE Flow Formed method uses an improved cast material that is denser, allowing for a lighter and stronger wheel than Low Pressure Cast (LPC) materials used by other flow form wheel companies. ACE applies the latest Cold Vertical Flow Form Technology, administering a steadier spin with consistent metal temperature. Thus producing a consistently higher quality wheel than hot horizontal flow form methods.

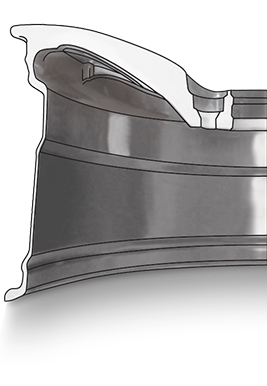

The Flow Formed process is started

by placing a pre-heated Casted Wheel

on a specially designed inner barrel mold.

Rollers press into the wheel as it spins on

the mold, flowing the aluminum thinner,

forming the shape of the inner rim; all while

increasing the tensile strength.

The inner rim profile is finalized to meet

tire mounting specifications. The final

product is stonger, lighter, with increased

metal yield and compressive strength.

The Flow Formed process is started

by placing a pre-heated Casted Wheel

on a specially designed inner barrel mold.

*Dual rollers press into the wheel as it spins,

moving upward to form the Lip.

Dual rollers press into the wheel as it spins on the

mold, flowing the aluminum thinner, and vertically

formingthe shape of the inner rim.

+25% Increased compressive strength

+100% More elongation characteristics

-25% Weight reduction

Made with Cold Vertical Flow Formed Technology

* all data depends on the wheel model design and production result.

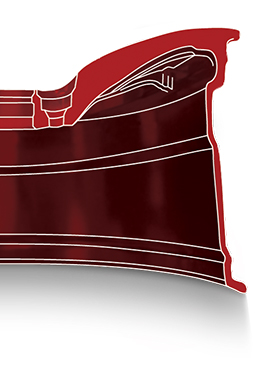

Wheel core contains less compressed material

Non-compressed barrel has less tensile strength

Prone to leaks or cracks on impact

Requires more material, making it heavier